Insights

Innovative technology key to addressing biofouling challenge

May 13, 2020

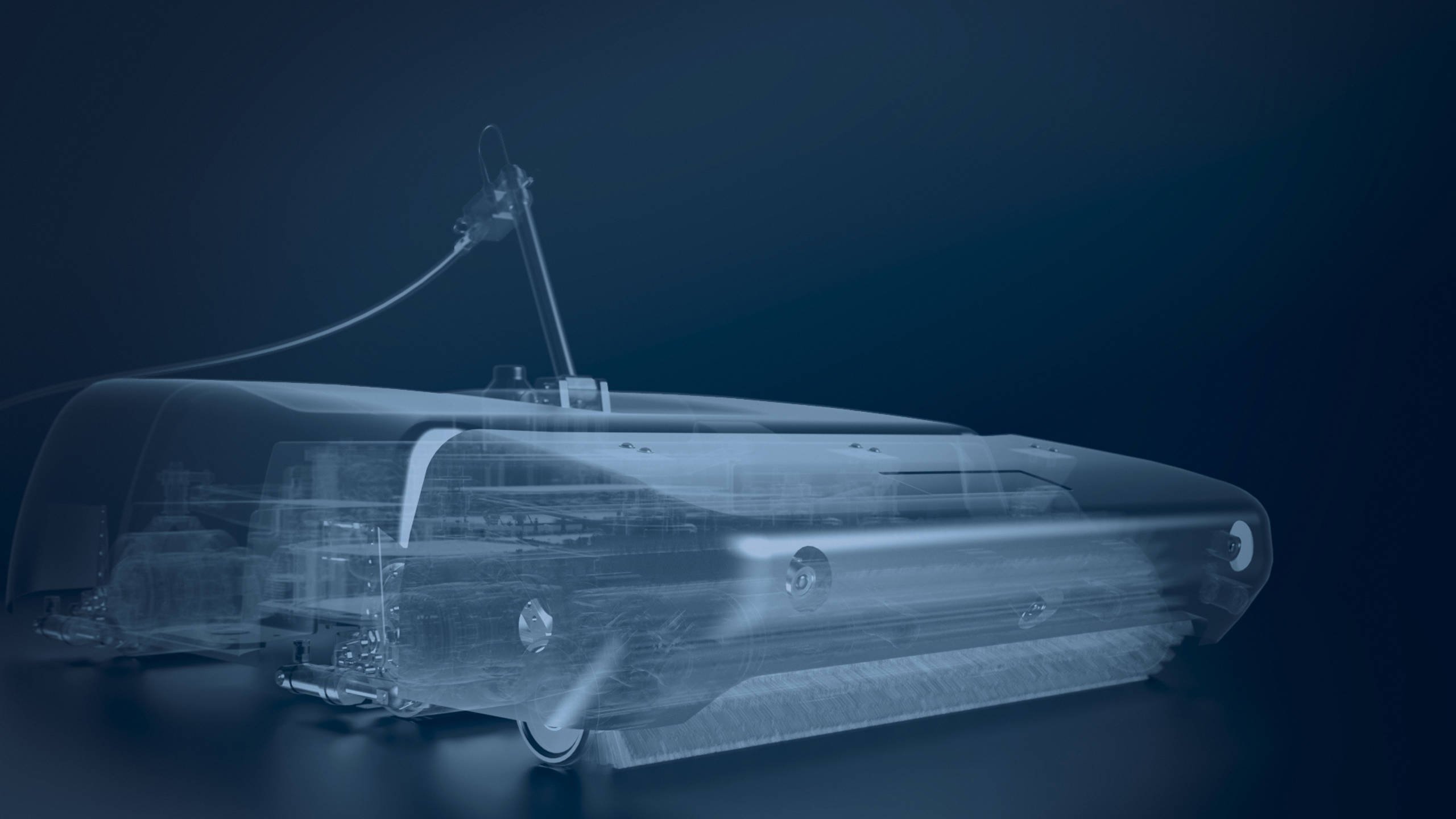

Jotun has, together with its partners, launched the new Jotun Hull Skating Solutions that uses a remotely operated robotic hull cleaning device called the HullSkater, designed to be carried with the vessel and deployed regularly to remove early-stage fouling. Jotun Maritime Insider asked Jotun’s industry partners to share their perspective on the new technology and how it can help address the global issue.

“Shipping is a traditional business and it takes time to establish new solutions as trustworthy products and services - it’s likely that many operators will continue to use divers to clean their hulls and propellers, but robotic cleaning will become an important part of the mix going forward as operators strive for fuel-efficient, sustainable operations,” says Egil Haugsdal, President Kongsberg Maritime.

The HullSkater is a leap forward more pronounced in character than the new paint formulations the hull coatings industry is always striving toward. “We think Jotun’s new solution is particularly interesting in the sense that Jotun is not only focusing on the chemistry, the constituents of the paint, but is also providing new technology to maintain consistently clean hulls. They are really driving change in the industry,” says Haugsdal.

Driving change

Meanwhile Hans Peter Havdal, business development manager of the Swedish multinational technology company Semcon, believes that the gains which can be made with the HullSkater are impossible to ignore. Having access to a vessel’s own device for this purpose, rather than relying on port-based cleaning regimes, robotic or otherwise, is key to the appeal of the service, he indicates. “From our perspective, the HullSkater represents a new, ground-breaking approach to hull cleaning and inspection using a robotic device that is on board the vessel,” he says. “If the owner/operator has the equipment already on board, then they can use it when it suits the vessel's schedule.”

“We believe the HullSkater will significantly reduce the risk of transferring harmful biological fouling across the oceans and into vulnerable harbours. This advantage comes on top of reducing fuel consumption and adds to the sustainability gain of the system.

“So there is more flexibility. There is also the advantage of having high-definition inspection capabilities through cameras which can monitor the quality of the cleaning work,” adds Havdal.

Self-sufficient

“I think the idea of the vessel being self-sufficient in terms of the capability to clean and inspect the hull is a clever solution and it would be natural for certain sectors in the industry to gravitate to such solutions in the long term,” says Geir Fagerheim, head of marine operations at Wallenius Wilhelmsen.

“From our side, we see it as a potential game-changer in the sense that the technology offers a totally new ability to maintain clean hulls,” Fagerheim continues. “Today, just the administration and overheads linked to actually managing this across a big fleet like ours are absorbing huge resources on the shore side and also have practical implications for the vessel operations. Jotun’s solution will handle the process more efficiently.”

The new solution could potentially alter the way coatings are applied in the future, he indicates. “Another important aspect of Jotun’s HullSkating Solutions - in addition to the HullSkater device - is that it offers the possibility of applying a new advanced paint with different characteristics, strong durability and less friction and resistance, and could help avoid long, expensive dockings, which we have every two or five years.”

However, like Haugsdal, Fagerheim believes that mass adoption may not be immediate. “It’s obviously dependent on how the new solution is brought to the market, how it’s sold and packaged,” he says. “The solution will certainly help to address the biofouling issue, but it is hard to say at this stage whether it will emerge as the new standard for inspection and cleaning. Much will depend on the individual operator’s needs and it’s likely that we will see operators that continue using not only traditional diver cleaning methods but also new robotic devices such as Jotun’s HullSkater.”

Wherever, whenever

“We think the new solution will help combat the global issue of biofouling since it will be installed on vessels and can be used anytime, anywhere,” say Espen Myhre, key account manager, and Bjørn Kristiansen, Internet of Things partner manager, at Telenor. “This, as we understand it, makes the solution unique compared to other solutions currently in the market and will help operators to address fouling settlement at a very early stage.”

Similar to the modern business model of satcoms providers, Jotun offers the HullSkater as-a-service, rather than the previous model of buying the system outright. Myhre and Kristiansen give their take: “Offering this solution as a service makes sense as it has a lot of market potential, especially when one considers the increasing market and regulatory pressures to operate sustainably.

“From our side, being able to participate as partners in the development of this solution is highly rewarding. Partnerships like this, where large Norwegian enterprises pool their competences and create a unique and future-oriented solution that can be brought to the world, are extremely interesting and make us proud. Norwegian companies have a lot to offer, especially when they work together. They can make a real difference on a global scale,” Myhre points out.

Prevention critical to sustainable operations

Solutions which address biofouling do a great service to the ecosystems of this planet, and any progress toward this goal, in whatever form, is to be commended; DNV GL head of maritime technical advisory Ellen Olsvik and principal consultant Sarath Raj, however, argue that the HullSkater in this particular form may contribute significantly. “Biofouling is a pressing industry issue. It increases ship hull resistance and decreases propeller efficiency, leading to higher fuel consumption and associated emissions to air. The prevention of biofouling, therefore, remains critical to sustainable operations.

“The exact savings from implementing the HullSkater solution are difficult to validate at this early stage as it’s not yet fully commercialized, but better management of hull and propeller surfaces will help prevent the build-up of fouling and contribute to reduced fuel consumption and lower GHG emissions,” opines Olsvik.

“In addition, ports and local and global authorities are increasingly concerned about the transfer of indigenous species and release of toxic waste from hull cleaning. International regulations are being evaluated and new ones will be issued, and the HullSkater solution may be an answer to these challenges and help create a win-win situation for both the environment and business.

“Certainly, there is significant scope to raise hull performance efficiency by maintaining a consistently clean hull through innovative, proactive cleaning and inspection technology,” adds Raj.

Increasing attention

As biofouling continues to attract an increasing amount of attention from states, regulators and port authorities around the world, it is likely that sustainability-focused companies will seek best practices and standards to improve hull maintenance and in-water cleaning.

Commenting on the subject, Ashok Srinivasan, manager, maritime safety & security at the maritime trade group BIMCO said, “It is BIMCO’s standpoint that our industry needs more environmentally sustainable solutions. Ship’s biofouling plays a part in the spread of invasive aquatic species (IAS) and indirectly impacts the greenhouse gas emissions (GHG). Ships need to be cleaned to curb the spread of IAS and reduce GHG emissions. In BIMCO’s opinion, ships need to be cleaned while they are in water as the cost of going for an out of water cleaning is prohibitively high. BIMCO looks favourably at newer technology that tackles these challenges while ensuring a clean environment."

For more information about Jotun Hull Skating Solutions and our partner’s perspective, visit our Hull Skating Solutions page.

Jotun has unveiled Jotun Hull Skating Solutions, an innovative, proactive and sustainable means to help ship operators maintain always cleans hulls in the most challenging operations. A primary component of Jotun Hull Skating Solutions is the unique, onboard Jotun HullSkater, the first robotic technology that has been purpose designed for proactive cleaning. In combination with the premium SeaQuatum Skate antifouling and associated services, Jotun Hull Skating Solutions will help ship operators combat early stage fouling, significantly reducing fuel costs, greenhouse gas emissions and the spread of invasive species.