Insights

How can industry meet the biofouling challenge?

tháng 7 09, 2019

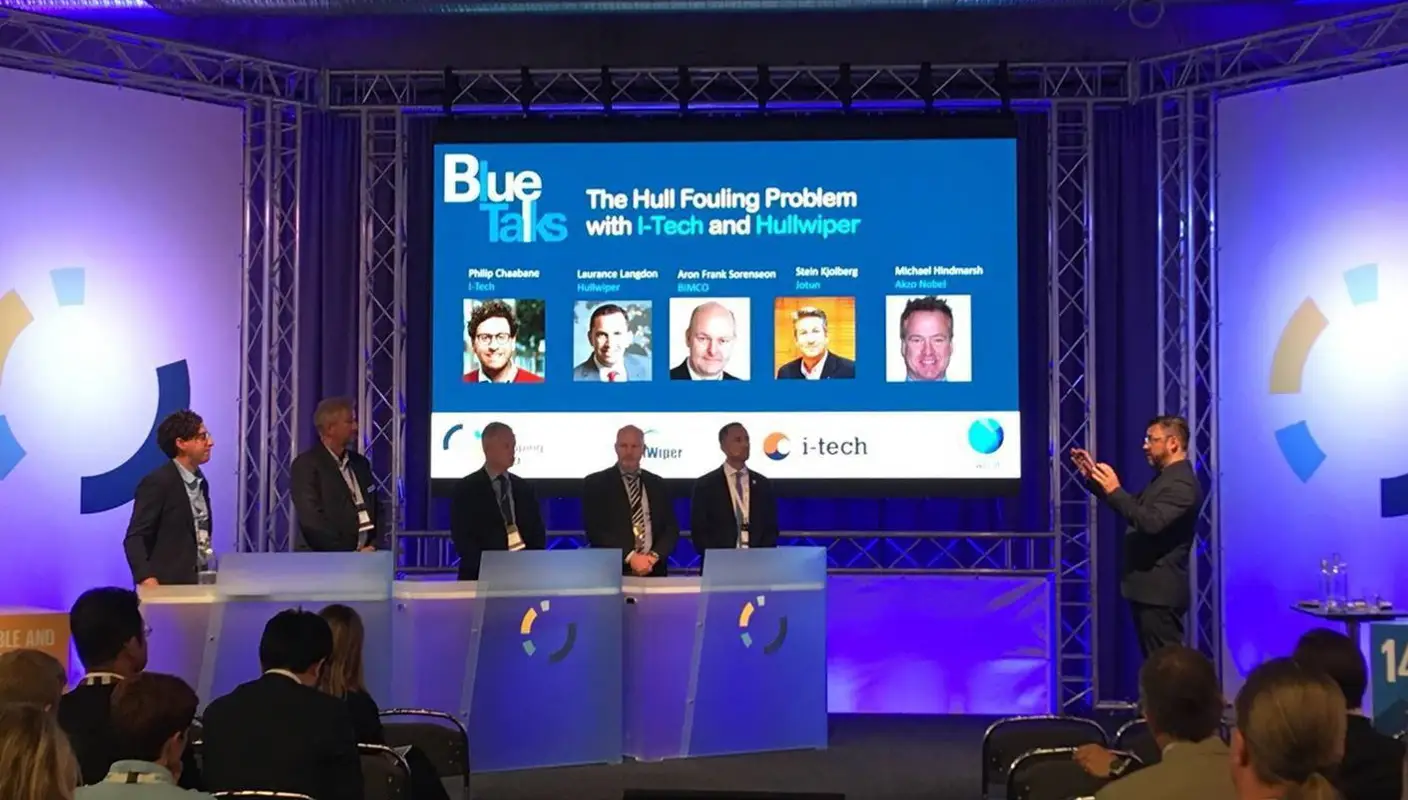

“Fouling remains a pressing issue as it significantly slows a vessel’s speed and adds to the fuel used which both increases operating costs and emissions. There are a variety of ways to tackle the issue, including coatings, cleaning technology and performance monitoring systems. However, not all stakeholders see the value. There’s a need for financial incentives and better alignment between the stakeholders,” said Jotun Global Concept Director HPS, Stein Kjølberg, when addressing delegates during the Nor-Shipping BlueTalks session titled ‘How can industry meet the biofouling challenge?’

Echoing Kjolberg’s comments, Michael Hindmarsh, Business Manager at Akzo Nobel said, “There are many products developed by the coating manufacturers, ranging from the high end to the low end but only 30% to 40% of ships are buying the best performing products. If everybody bought the high-end products then the problem of fouling, poor vessel performance and invasive species would be better managed. The truth is economics comes into it because the best performing products cost more money.”

“The market is becoming more complex as a new generation of owners, banks, funds, pool operators, coupled with charterers and regulators, are all pushing for more efficiency and transparency. Still, when it comes to biofouling, this is not being properly addressed because many in the industry are not fully questioning its impact on vessel performance,” pointed out Kjølberg.

Biofouling regulation on the horizon

Panellists agreed that the prevention of fouling remains critical to sustainable operations and possible biofouling regulation by the International Maritime Organisation (IMO) may well force operators to change their approach to addressing biofouling.

“Up to now there’s no global regulation but that might change as many expect that biofouling will be the next environmental issue that the IMO will be pursing. Also, it is worth noting that some countries and states have already taken steps and implemented their own regional or local requirements,” said Kjølberg. “Many operators already take voluntary action to address biofouling, but new regulations could encourage more operators to take-up advanced coating technologies to meet the requirements. And, in doing so, this could also help to make their vessels more attractive to potential charterers.

“At the same time, we all know that the shipping industry comprises different actors, with different roles and expectations. Tonnage suppliers, operators and charterers all have different interests and the investment strategy gap between them needs to be closed to benefit the industry fully in terms of efficiency and environmental sustainability,” added Kjølberg.

“There is a lot of environmental regulation on the table and it would not surprise me if the IMO also regulates biofouling,” added Hindmarsh. “Once the industry moves towards biofouling management plans, like we are seeing in New Zealand, Australia and California, then this is a way of mitigating the risk of fouling and invasive species.”

Co-panellist, Aron Frank Sørensen, Head of Maritime Technology and Regulation, BIMCO, also believes new regulations could help to encourage operators to invest in sustainable practices more actively. “We are in favour of regulations. It will be interesting to see the outcome of the IMO-led GloFouling project. The industry needs IMO’s global approach.

“Biofouling is a big headache for the industry and that is why BIMCO has developed an in-water cleaning standard, in collaboration with the paint manufacturers, cleaning companies and owners. We strongly believe these three entities should cooperate more because the industry would gain from it,” added Sørensen.

Call for more innovation

The session also focused on technologies that are being developed to help achieve fouling-free ships. Philip Chaabane, Chief Executive Officer, I-Tech, emphasised investment in new technologies will be critical going forward. “Adopting state-of-the-art antifouling coatings and technologies makes sense. The cleaner the ship, the greater the financial incentive which creates a win-win situation for both the environment and business.” I-Tech has developed the antifouling ingredient Selektope, which is attracting growing interest in the market.

The economical and environmental impact of foulings, combined with the changing regulatory and operational conditions in the industry, are adding to the pressure for more innovation and improvement – also when it concerns hull cleaning methods according to Laurance Langdon, General Manager at Hullwiper. “We predict underwater robotic cleaning is set to play a bigger role to combat fouling issues. There are multiple benefits, not least significant fuel savings, no downtime and eco-friendly cleaning methods,” argued Langdon.

The rapidly progressing digitalisation is also having an impact as operators look for ways to achieve fuel-efficient, sustainable operations agreed Kjølberg and Hindmarsh. “The driver for this is the desire to improve operating efficiency” commented Hindmarsh. “This development also benefits the coating manufacturers who use vast amounts of data to show customers the potential performance benefits of fouling control coatings.”

Kjølberg sees digitalisation as a challenge and an opportunity. “Using big data, in an environment where capacity is already stretched, is a challenge for some operators. That said, those who are ‘going digital’ see the benefits. Also, using digitalisation can open up new opportunities in the form of financial incentives (better terms from banks and financial institutions) discounts in connection with port, class and insurance fees, and commercial pool points relating to efficiency ratings. Standards, such as ISO 19030, can also be used for transparent monitoring and reporting of changes in hull and propeller performance,” added Kjølberg.

“New regulations, coatings and cleaning technologies and ways of doing business will, for sure, bring challenges but paint manufacturers also need to change and innovate if they are to help their customers - and the industry – to tackle the global issue of biofouling. It’s not just about providing paint any longer,” concluded Kjølberg.