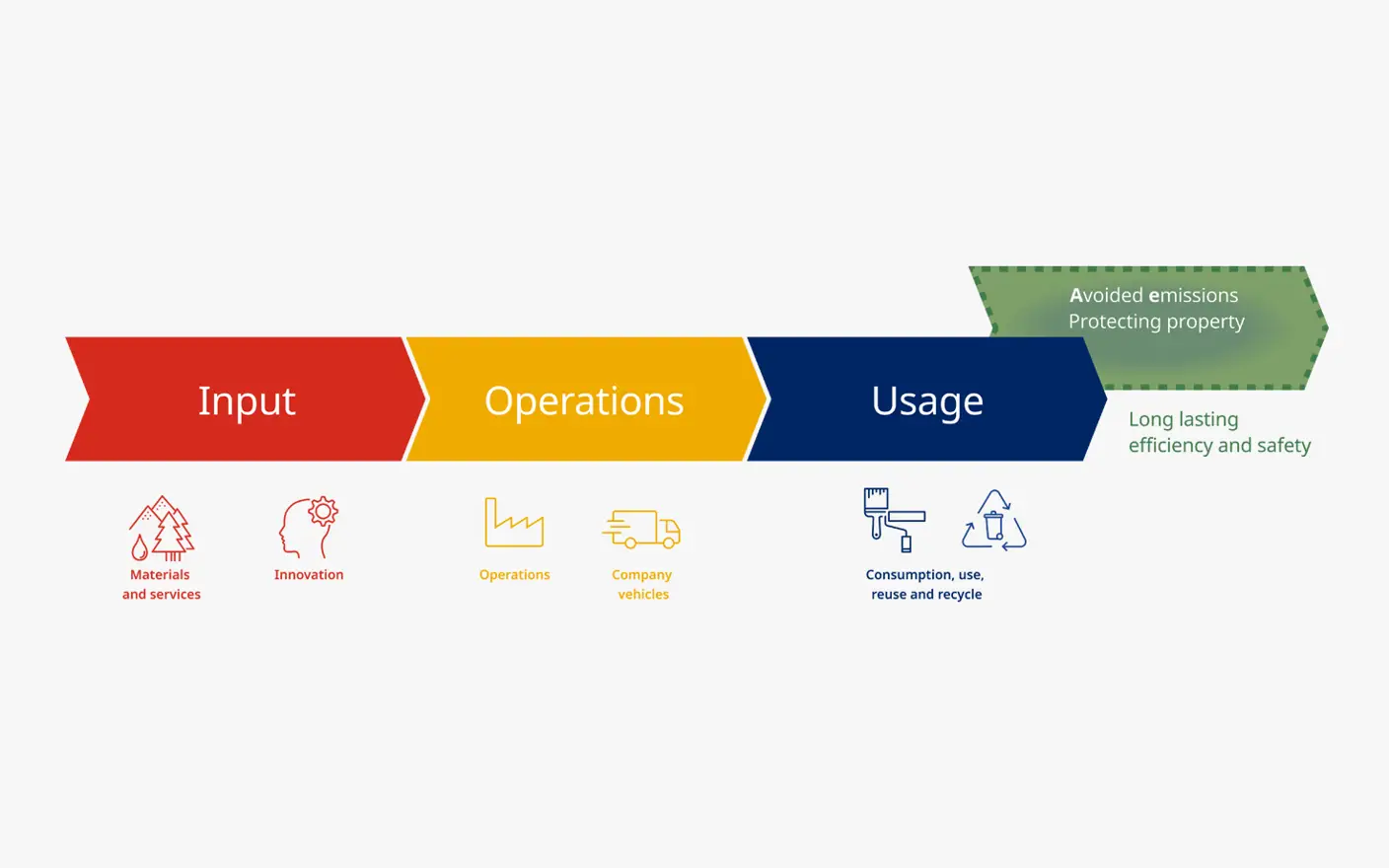

In Jotun's operations, our goal is to minimise environmental impacts and create safe working conditions. This also results in economic benefits, reduced risks and competitive advantages.

Sustainability as a part of building standards

Jotun focuses on improving existing facilities and increased use of the environmental footprint approach as a tool for design and efficiency of new factories and facilities.

In the design of the new factories, we consider aspects which support more efficient and environmentally friendly production. This is embedded in Jotun's Engineering Standard. Examples of important initiatives we have introduced include solar panels, bulk deliveries of raw materials, and the reuse of process water and solvents.

Measure and manage

Since 2010 we have monitored and reduced use of energy and solvents, as well as our carbon footprint, waste and VOC emissions per ton produced. Further, we set goals to eliminate inefficiencies, reuse materials and improve our environmental performance.

Energy consumption is the highest contributor to the carbon footprint from our operations. We therefore continuously work on increasing our energy efficiency and the share of renewable energy.

Other initiatives include reduction and reuse of plastics, and reprocessing of water, waste and paint. This is done through our HSEQ Management System, where all units are required to have local improvement programmes.

Read more about HSEQ.

Transport and logistics

In most countries where we operate Jotun uses external transport suppliers and we select sustainable and low-carbon suppliers whenever possible. We focus on warehouse and vehicle capacity optimisation for efficient supply to customers, while ensuring safe and sustainable packaging and transport.